THM125C/3T40

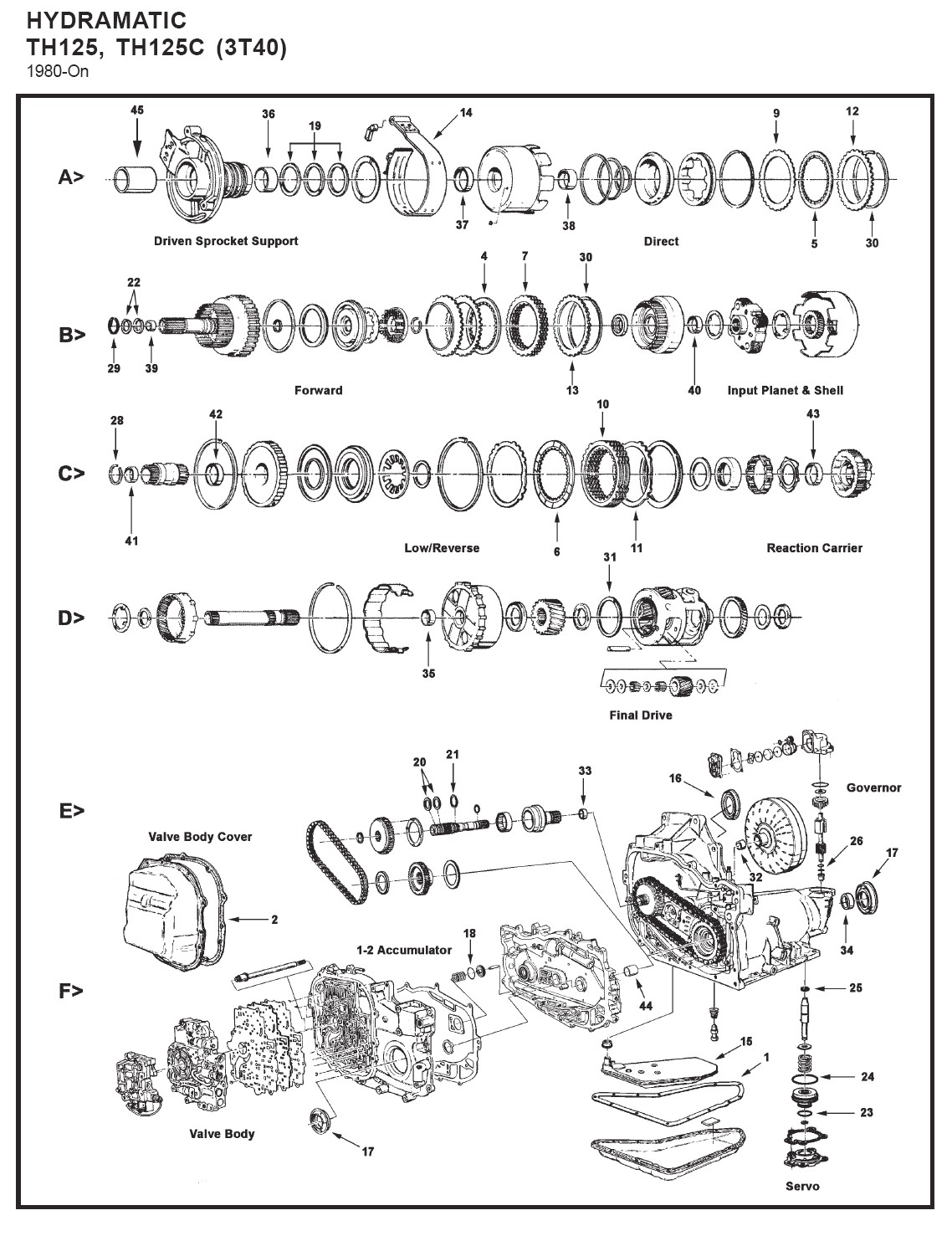

The major components of this transaxle are:

The fluid pressure and shift points are controlled by throttle opening via a throttle valve (TV) cable.

The transaxle can be operated in any of six different modes shown on the shift quadrant.

P- Park position prevents the vehicle from rolling either forward or backward

R- Reverse allows the vehicle to be operated in a rearward direction

N- Neutral allows the engine to be started and operated without driving the vehicle.

D- Drive position is used for all normal driving conditions. It provides three gear ratios plus converter clutch operation.

2- Manual Second is used to provide acceleration and engine braking.

1- Manual Lo is used to provide maximum engine braking.

1st and 2nd gears may be selected at any vehicle speeds.

Gear Ratios

| First | Second | Third | Forth | Reverse |

|---|---|---|---|---|

2.840 |

1.600 |

1.000 |

N/A |

2.067 |

"THM 125C" MODEL & FINAL DRIVE RATIO TABLE

FINAL DRIVE RATIO |

2.84 |

3.06 |

3.33 |

|---|---|---|---|

MODEL |

BDC, BJC, CBC, CMC, CRC, CJC, CUC, CNC,CTC, CXC, KDC, LKC, PDC, PKC, PMC, PPC, PNC, PSC, PWC | CAC, CCC, CSC, CDC, HLC, HRC, JAC, JDC, JWC, PHC, PTC, TAC, TBC | CPC, HYC, HZC, JFC, JKC, JMC, JNC, JPC, JTC, JUC, JXC, LHC, RAC, RCC |

RANGE REFERNCE CHART

RANGE |

GEAR |

DIRECT CLUTCH |

INTERMEDIATE BAND |

FORWARD CLUTCH |

ROLLER CLUTCH |

LO-REVERSE CLUTCH |

|---|---|---|---|---|---|---|

DRIVE |

FIRST SECOND THIRD |

APPLIED |

APPLIED |

APPLIED APPLIED APPLIED |

HOLDING

|

|

INTERMEDIATE |

FIRST SECOND |

|

APPLIED |

APPLIED APPLIED |

HOLDING

|

|

LO |

FIRST

|

|

|

APPLIED

|

HOLDING

|

APPLIED

|

REVERSE

|

REVERSE

|

APPLIED

|

|

|

|

APPLIED

|

Maintenance Information

Transaxle fluid check (every 3,000 miles or 3 months)

|

Transaxle fluid and filter change(every 30,000 miles or 30 months)

|